Staging at Zero-Waste Restaurant Silo, by Junior Sous Chef Lulu

Published on: March 27, 2024

Here at Social Pantry, we invest in our team by promising chefs’ long-term growth and development and support them in widening their culinary horizons through staging.

If you’re not familiar with the term, a stage (pronounced “stahj”) is a period of work experience that a chef takes part in to experience different kitchen environments and be exposed to new techniques.

Our Junior Sous Chef, Lulu, has been with the team for over two years now, and has previously completed a stage at the modern Middle Eastern restaurant, Bubala. This year it was her turn to temporarily join the team at the world’s first zero-waste restaurant, Silo.

We’re handing over to Lulu to tell us all about how she spent her three days in the Silo kitchen, what she was most inspired by, and the techniques she learned that she’s looking forward to introducing into the Social Pantry kitchen…

My three days at the restaurant were fully packed with new terminology, new techniques, and a new environment. It’s safe to say I learnt a lot! As someone who was brought up surrounded by jars of pickles, dried wild mushrooms, and a vegetable patch in the garden, I thought I knew a lot when it came to preserving and fermenting food, but it turns out I was very wrong…

A Champion of Closed-Loop Cooking

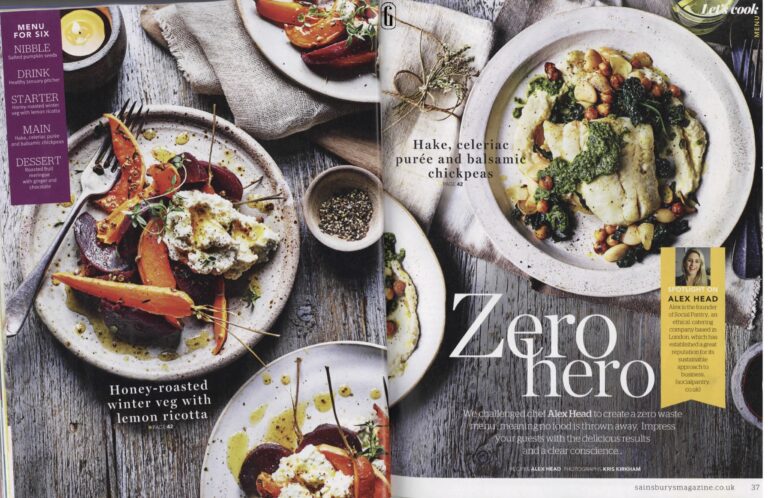

Silo was the perfect place to stage as it completely encompassed Social Pantry’s sustainability and zero-waste ethos. The way the Silo team strive to waste as little as possible is incredible, from utilising the ends and trimmings of their vegetables to make a rich and sticky treacle, to using all the offal from the animals to enrich their dumpling fillings and sauces. Old sourdough starters are turned into miso, pasta dough, sauces, their signature homemade quavers, and so much more. As someone who has always had a focus on preserving ingredients and minimising waste, this experience has made me reflect on what great things we do already at Social Pantry, in terms of minimising waste and using sustainable sources, but also what we can do to improve going forward, and into the future.

Biggest Learning to Implement

That simple fermentation doesn’t have to be a long process that involves lots of technical knowledge and skill. In reality, making kimchi out of old vegetables can take just 3 days. Making a fruit cheong (a lacto-fermented syrup) is a week-long process and makes the fruit taste sweet, salty, and alcoholic all at once. These flavours are not impossible to recreate, but the way these flavours enhance ingredients in a dish is unlike using salt, acid, or fats and therefore is something to strive for. These fermentation techniques are something I would like us to implement in the Social Pantry kitchen, as an additional way of utilising our produce and trimmings whilst introducing new flavours to our menus.

Trading with Pirates

Silo use an incredible array of suppliers with whom they work closely to collaborate in minimising the use of single use plastics and keeping CO2 emissions at a minimum. One of the latest moves made by the restaurant is the use of a pre-industrial transport system for produce and products which the Silo team refer to as “trading with pirates”, utilising a ship originally launched in 1916 and now called The Gallant, to bring items to the UK from overseas, the old -fashioned way. The first lot of cargo Silo received from The Gallant was panela sugar, brought from the Caribbean coast of Colombia, and harvested from the indigenous Kogi tribe in the Sierra Nevada mountains. This sugar is used in the majority of their ice-creams, adding a deeper, richer flavour.

New Techniques

At Silo, their techniques are far more ancient in origin and complex than some of the preservation techniques I have been used to using in the kitchen, with most of their jars in the fermentation cupboard still requiring a few months – or even years – to fully mature to their desired flavour. The three main terms I heard the most during this time were, amazake, garum, and koji.

Amazake

Amazake literally means ‘sweet sake’ and you can get both alcoholic and non-alcoholic versions. It’s a traditional Japanese fermented sweet drink, which in modern times has been transformed into desserts, snacks, and dressings. Amazake is the stage before it becomes known as Sake, its flavour often being sweet, sharp, and warming to the throat.

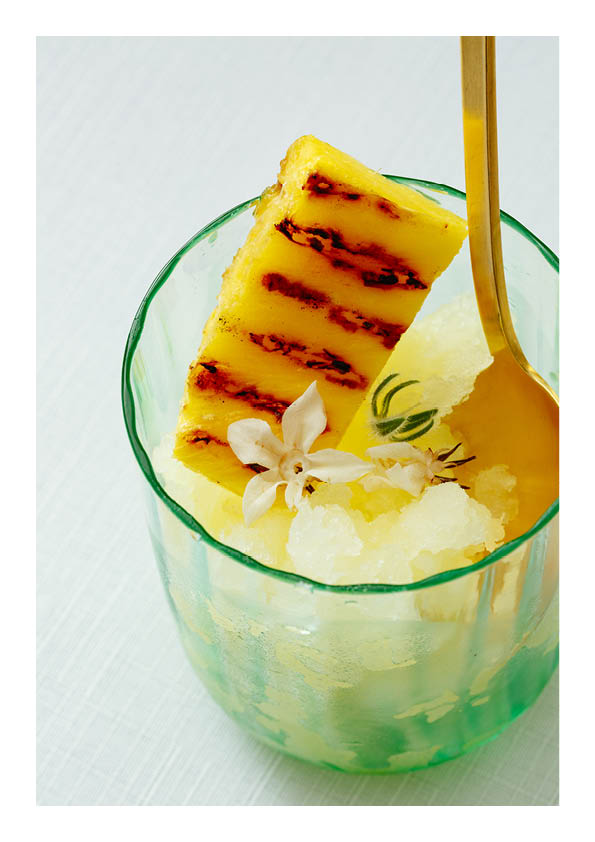

At Silo the amazake was used in their main dish as well as their first dessert. In their main dish it was used to flavour the mutton, coating it fully and leaving to absorb the complex flavour overnight before it was finished off over the open fire to order. For their first dessert, the amazake was turned into an ice-cream, smooth and creamy in texture but sweet and sharp in flavour. It was then topped with raspberry cheong which enhanced its creamy properties.

Koji

Hailed as Japan’s “national fungus,” koji mould plays a foundational role in much of the country’s traditional cuisine. Koji is for various culinary purposes, including the production of alcoholic beverages like sake or shōchū, or invaluable condiments like miso, mirin, and shōyu (soy sauce). Like yeast starters in bread making, koji kickstarts the fermentation process when added to other base ingredients, like soybeans, rice, or wheat grains like barley. When applied to proteins, koji acts as a curing agent in the production of charcuterie. The enzymes present in koji moulds transform starches and proteins into amino acids and sugars, the resulting flavours define the realm of umami: sweet, savoury, salty, with an undertone of pleasing funk. At Silo, koji is used throughout their menu and dishes, often used as a flavour enhancer.

Garum

A delicacy in ancient times, garum was originally fermented fish sauce made all around the Mediterranean basin. Garum was only made with small, fish like sardines or mackerel, brine and given a lot of time to ferment – a year most commonly. At Silo, they have developed a new version of making garum which doesn’t solely rely on the microorganisms and enzymes present in the fish’s gut to create the chemical processes. With the help of koji there is scope to experiment with a range of high-protein ingredients to extract umami-rich flavours that are less salty and tangy, and richer in complex, subtle flavours. The garums in the fermenting cupboard at Silo varied from the traditionally fish based garums, through to pure vegetable garums and complex meat garums. These were then used in most sauces served alongside their main dish element.

On the Other Side of the Pass

On my final evening at the restaurant, I was lucky enough to be seated for dinner. This included Silo’s incredible 7 course tasting menu, paired with their wine flight. The staff treated me as any other guest, fully immersing me into the Silo experience.

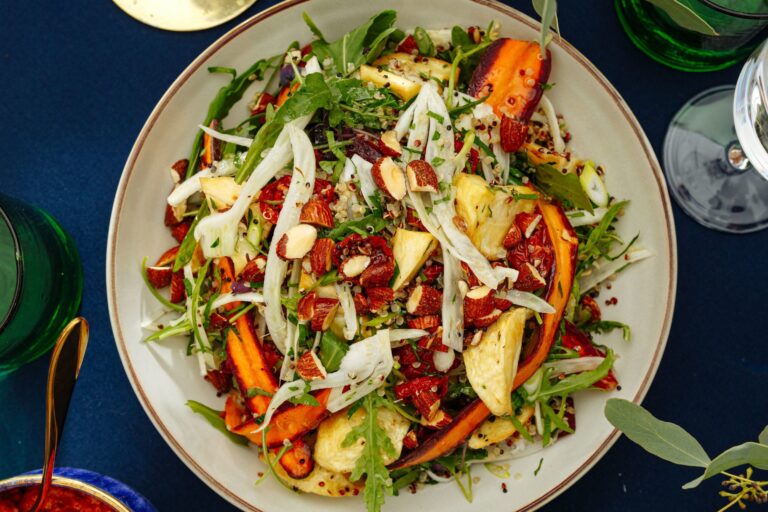

Their menu is mostly made up of ingredients native to the UK. The first snack you are greeted with is a foraged plant known as Alexander, or Horse Parsley. These were planted by the Romans along the side of the roads to allow their horses to graze as they walked for many miles. Their sea bream is all caught by one man and one boat using a fishing rod, ensuring sustainability is at the forefront of all produce used at the restaurant. The tasting menu is very flexible as the supply of fish may not always meet the demand. Wine is equally as interchangeable to their menu as the food – it can change regularly depending on what is available and when they receive it from overseas using the traditional cargo ships.

The chefs are incredibly talented in adapting to the everchanging list of available ingredients, making it a totally unique place of work and dining experience. I thoroughly enjoyed my time in the Silo kitchen and look forward to expanding my knowledge of zero-waste cooking techniques even more after this incredible experience!

We have sent many chefs to Silo over the years to learn from their great kitchen team! If you’d like to read more about some of our chef’s experiences over the years, take a read of Grace’s stage from last year, or Amy’s stage from 2022, or find out what a day in the life is like for our Head of Development Sarah, who completed her own stage at Silo in 2021.